The smart home cleaning market is booming, and window cleaning robots are rapidly moving from a novelty to a necessity for modern households and commercial buildings. For brands and entrepreneurs looking to enter or expand in this lucrative space, finding the right manufacturing partner is the single most critical decision. An automatic window cleaning robot manufacturer is not just a supplier; they are your strategic partner in product quality, innovation, and market success. This guide will walk you through the key factors to consider when selecting an OEM factory for your robot window cleaner business.

1. Assess Core Technological Capability and R&D Strength

The heart of a smart window cleaning robot lies in its technology. Look beyond assembly lines and inquire about the partner's R&D investment. A true leader like LINICINCO (Dongguan Lingxin Intelligent Technology Co., Ltd.) demonstrates this with a dedicated team of over 65 technical experts. This depth allows for genuine innovation in suction power algorithms, path planning for different glass types (like curved or frosted glass), and safety sensor integration. Can they develop a custom window cleaning robot for your unique market segment? Their portfolio of over 100 patents is a strong indicator of proactive, rather than reactive, development.

Ask potential partners about their latest R&D projects. Are they working on AI-visual recognition for stain detection? How do they handle the challenge of cleaning corner edges? The answers will separate a true smart window cleaning robot factory from a mere assembler.

2. Evaluate Manufacturing Scale and Quality Control Systems

Scale matters for consistency and cost, but quality control is paramount. A reliable Window Vacuum Cleaner Factory should have transparent processes. LINICINCO operates two specialized factories with a total area of 75,000 sqm and an annual capacity of 5 million units. This scale ensures they can handle large Robot Window Cleaner Wholesale orders without compromising on lead times.

Visit the production line if possible. Look for standardized workflows, in-line testing stations (for suction, battery, sensor function), and a clean, organized environment. Inquire about their QC protocol: how many checkpoints are there from component arrival to final packaging? A partner with its own mold room, like LINICINCO, has greater control over part precision and quality from the very beginning, which is crucial for Glass Cleaner Machine OEM&ODM projects.

3. Verify Compliance and Certification

Selling in global markets requires adherence to strict safety and environmental standards. Your chosen automatic glass cleaning robot supplier must provide all necessary certifications. Essential marks include CE (for the European market), RoHS (Restriction of Hazardous Substances), and FCC (for the US). These are non-negotiable for market entry.

Certification Proof: A trustworthy partner will readily provide certification documents. For instance, LINICINCO holds both CE-RED and RoHS certifications, which validate that their Winbot Manufacturing in China processes meet international directives for safety, health, and environmental protection. Always request to see these certificates for your specific product model.

4. Analyze Product Portfolio and Customization Flexibility

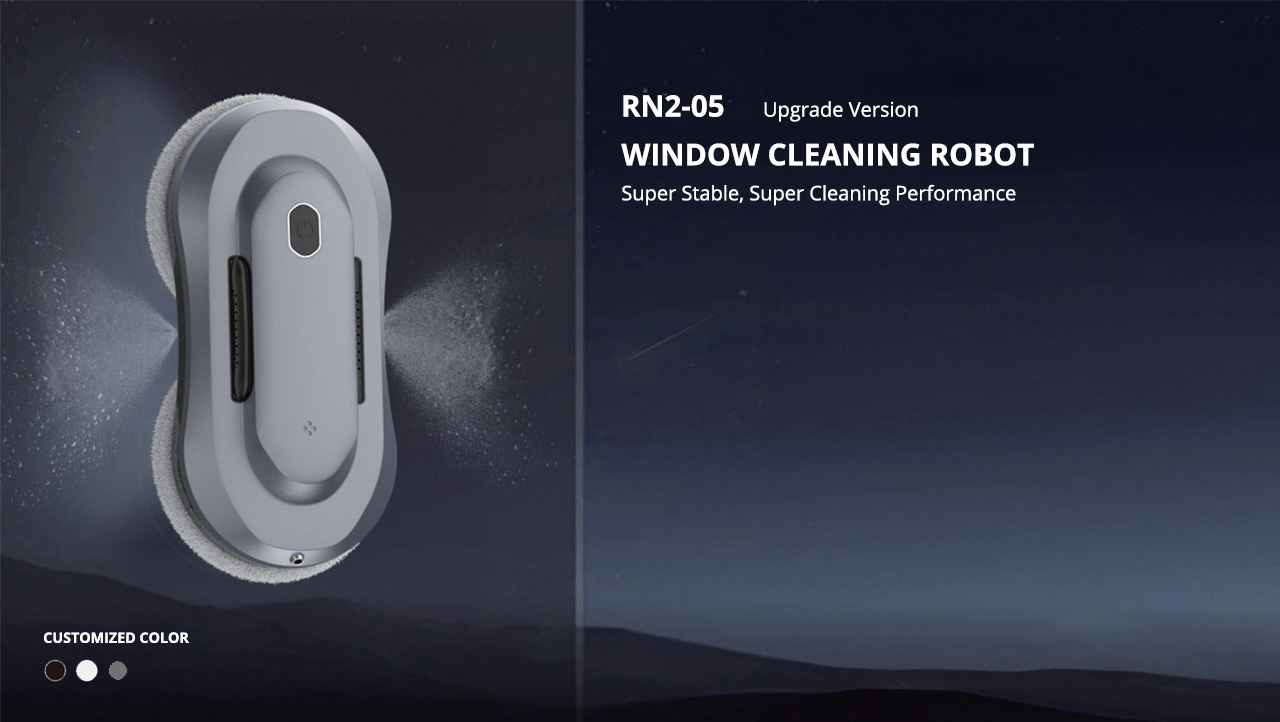

Does the manufacturer offer a one-size-fits-all product, or do they have a diverse range? A strong smart window cleaning robot OEM factory will showcase different form factors and functionalities. Look for variety: square robots with four nozzles for intensive cleaning, round models for maneuverability, or models with dual spray systems for tackling tough grime.

This diversity indicates a deep understanding of market needs and the technical ability to execute. For OEM and ODM services, flexibility is key. Can they modify the design, software UI, or branding elements? Can they integrate a specific battery or motor you prefer? Discuss your vision for a custom window cleaning robot early in the conversation to gauge their willingness and capability to collaborate deeply.

5. Consider Supply Chain Stability and After-Sales Support

A robust supply chain is your defense against market disruptions. An established robot window cleaner supplier should have long-term relationships with tier-1 component suppliers for critical parts like motors, lithium batteries, and microchips. This ensures consistent quality and shields you from volatile component shortages.

After-sales support is equally critical. What is their policy on defective units? Do they provide technical documentation, marketing materials, or spare parts support? A partner invested in your long-term success will offer comprehensive support, helping you build a reputable brand. Companies like LINICINCO often provide such end-to-end partnership, which is invaluable for brands focusing on Electric Window Cleaner OEM.

Making the Strategic Choice

Choosing the right automatic window cleaning robot manufacturer is a strategic investment. It's about aligning with a partner whose technological prowess, manufacturing rigor, and business ethos match your brand's ambition. By thoroughly evaluating R&D, production, compliance, product range, and support, you can forge a partnership that doesn't just supply products but fuels your growth in the competitive smart cleaning landscape.

For businesses seeking a reliable partner with proven expertise in Winbot Manufacturing in China and comprehensive Glass Cleaner Machine OEM&ODM services, exploring a collaboration with LINICINCO could be a decisive step. You can learn more about their capabilities and initiate a conversation by visiting their official website at www.cleverobot.com, or contacting them via email at molly@cleverobot.com or WhatsApp at +86 13424841625.